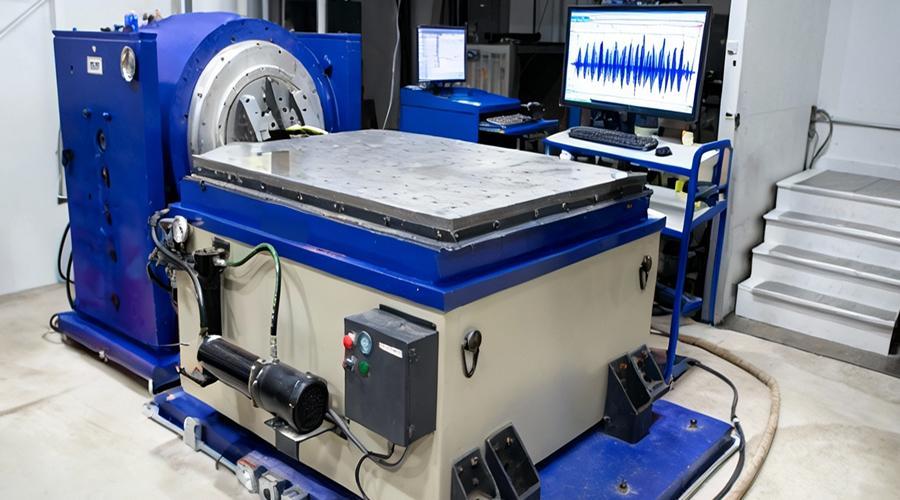

What is Shock and Vibration Testing?

Shock and vibration testing is a vital part of manufacturing reliable and durable appliances. Today, if you manufacture a product, you must conduct shock and vibration testing on your products before selling them in the market. That will show your product is trusted and works as expected. Let’s explore and get to know the essence of shock and vibration testing and its importance. Here we go!

What is Shock and Vibration Testing?

Shock and vibration testing is an essential testing method that involves assessing product durability against real-world stress. It aims to check the durability and reliability of the product before placing it to the market. Shock and vibration testing can be conducted independently or together within a protocol. It involves subjecting the product to mishandling, dropping, and multiple methods of shipment. That ensures checking the overall performance under extreme conditions. NABL and BIS testing lab helps manufacturers see how their products perform at different evaluation stages.

Importance of Vibration and Shock Testing

If you’re wondering about the importance of vibration and shock testing, let’s explore why it’s essential for you. We’ve outlined the main key importance of shock and vibration testing in India:

Improved Reliability and Durability

When a product manufacturer performs shock and vibration testing on its product, it helps them to identify loopholes and hidden manufacturing defects. In the product testing, a team of testing experts drops, bumps, and analyses the product with its consistent movement. This approach helps them check weaknesses and areas for improvement. Vibration and Shock testing uncovers areas prone to mechanical fatigue, wear, and other forms of damage over time.

For example, a vibrating refrigerator can cause damage to sensitive parts of the electronic components. It empowers manufacturers to correct the design and ensure reliable mass production.

Regulatory Compliance and Market Access

There are many strict standards that product manufacturers have to follow to sell their products effortlessly in the market. NABL (National Accreditation Board for Testing and Calibration Laboratories), BIS (Bureau of Indian Standards), and IEC (International Electrotechnical Commission) are some of the very important authorities that decide certain standards for maintaining a particular level of quality, safety, and performance in the product.

As a manufacturer, you have to follow them and make your product align with their rules and regulations. Thankfully, connecting with a approved BIS and NABL testing lab ensures you can check that your product is aligned with essential local and global standards. That ultimately empowers you to show high quality and build customer confidence.

Enhanced Safety

Shock and vibration testing is essential for industries like aerospace, automotive, and defence to check product defects for public safety. As a manufacturer, it is also important for you to prevent any catastrophic failure. This approach always keeps you on the safe side and maintains the trust of your products. A shock test and vibration test expert ensures the product does not break off or fail in a way that could cause injury or significant property damage. It is needed to perform product performance testing on home appliances, electronics, and refrigeration products.

Reduced Costs and Higher Satisfaction

A product that is double-checked by the manufacturers and an expert team of testers is less likely to have any kind of defect. Rigorous shock testing experts ensure scanning for small and major defects. They analyse each part of the product for malfunctions and ensure better quality. When you pass your product through performance testing, you avoid product returns and ultimately reduce the overall manufacturing costs.

How to Connect with the Right Shock and Vibration Testing Lab?

Want to know how to connect with the right shock and vibration test lab? The answer lies in understanding a few key factors. Most business professionals run after cheap services and ignore the quality. That is something that you need to avoid when making the decision. Let’s explore 2 major factors that will help you choose the right shock and vibration testing lab. Here we go!

Accreditation and Certifications

This is the first factor you should consider before making a choice. Find out if NABL, BIS, or other leading authorities accredit the product testing lab. An accredited company means that its shock testing services conform to leading national and international standards.

Product manufacturers always prefer to have their products tested by a certified and accredited testing laboratory. This idea provides them with multiple benefits. First, they can ensure high quality and performance of their products. Second, they can apply for certification and simplify the process. Lastly, their product, which is tested by shock vibration testing services, demonstrates the reliability and trustworthiness of their product.

Range of Services and Technical Capabilities

Choose a shock and vibration testing lab that provides a full range of testing services. Their support should not just be limited to shock and vibration testing; they also provide environmental testing, mechanical testing, performance testing, and much more. If you choose so, their support will help you perform other testing services as well.

Moreover, a testing laboratory that offers a wide range of product testing services demonstrates extensive expertise, which includes skill in shock and vibration testing. By connecting with such testing laboratories, you can avoid the need to connect with multiple labs. Furthermore, choose the solution that is equipped with modern and advanced equipment, including environmental testing chambers, for accurate, safe, and precise testing.

Bottom Line

Shock and vibration testing methods help product manufacturers test the safety, durability and performance of products. Before mass production, you can pass your model through these tests to see how your product is performing. If testing experts find any loopholes and product weaknesses, you can rework them before launching them in the market. The in-depth reports that testing experts provide reveal hidden loopholes of products, ranging from durability and lifespan to product quality.

Connect with ACE Test Labs- best shock and vibration testing in India to get a range of testing support. We can test different product categories and brands at competitive prices.

Categories

Related Blogs

What is Salt Fog Testing?

What is the Bureau of Indian Standards?

Best BEE Testing Laboratory in Haryana

Best Testing Laboratory in Chennai

What is Uninterrupted Power Supply Testing (UPS Testing)?

Electronic Clock Testing as per IS 302-2-26:2014/2024 Standard

Fan Testing as per IS 302: Part 2: Sec 80: 2017 Standard

BIS Certification: Process, Types and Validity

Advantage and Disadvantage of NABL Accreditation